Call us: 08045479549

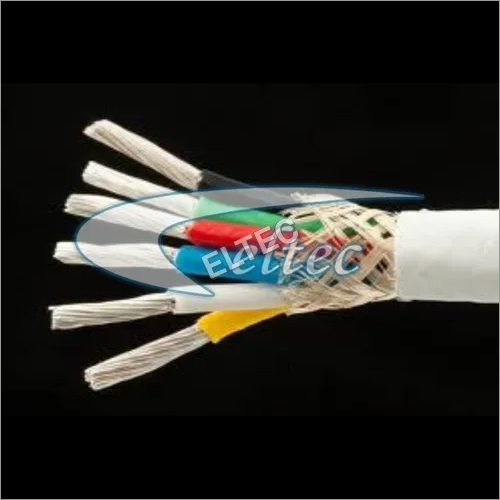

PTFE CABLE

Product Details:

- Product Type PTFE CABLE

- Material Silver Plated Copper / Nickel Plated Copper

- Usage Industrial

- Rated Voltage 600-1000 Volt (V)

- Color White

- Click to View more

PTFE CABLE Price And Quantity

- 50 INR/Meter

- 100 Meter

PTFE CABLE Product Specifications

- White

- Industrial

- PTFE CABLE

- Silver Plated Copper / Nickel Plated Copper

- 600-1000 Volt (V)

PTFE CABLE Trade Information

- 7 Days

Product Description

PTFE CABLE

PTFE Cables have outstanding mechanical & electrical properties. They are heat resistant and have its application for temperature range from -65 C to 260C.

In most adverse industrial conditions, where chemical fumes & other liquids make all other types of cables are vulnerable, PTFE polymer becomes an excellent solution as it is chemically inert to most of industrial chemicals. Its outstanding di electric properties even at high elevated temperatures make it suitable for harsh industrial applications.

The PTFE equipment wire are as per US Military MIL W - 16878D and Indian defense specifications JSS 51034.92. As per these standards, PTFE wires are classified in three main working voltage grades.

| GRADE | SPARK TESTING | DIE ELECTRIC TESTING |

| ET (250 V) | 2500 V ACrms | 1500 V ACrms |

| E (600 V) | 3400 V ACrms | 2000 V ACrms |

| EE (1000 V) | 5000 V ACrms | 3000 V ACrms |

Constructional details

| Conductor | Soft Annealed silver plated or nickel plated copper wires or as per client requirement. |

| No. of cores | Single core and Multi core |

| Core Insulation | Spirally Wrapped PTFE Tape and Sintered |

| Core Laying | Twisted |

| Screening | Silver Plated Copper / Tin plated copper / SS braiding as per clients requirement |

| Outer Sheath | Spirally Wrapped PTFE tape and Sintered. |

| Braiding | Fine annealed soft mirror finished SS WIRE |

ADVANTAGES OF PTFE insulated WIRES & CABLES

High dielectric values resulting in excellent resulting in space & weight saving

Wide operating temperature from -65 C to 260 C

Inert to most chemicals & fluids even at elevated temperature & pressure.

Unaffected by oils, lubricants & hydraulic fluids.

Non flammable, non toxic, resistant to solder iron damage.

Suitable for high frequency operation.

Immune to agene, fungus & water absorption.

Resistance to UV resistance & stress creaking.

High strain & abrasion resistance.

FEW IMPORTANT PTFE WIRES & CABLES APPLICATIONS:

|

|

|

|

|

|

|

|

|

|

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese